Burner Management Systems (BMS)

Our burner management systems offer the latest technology in programmable logic control (PLC). In partnership with our custom software, the PLC controls the system safety limits, valve control and operator inputs through a graphically enhanced workstation. All of the inputs are individual inputs to the PLC. The custom software monitors these inputs and prompts the operator through burner start-up via the message display. Any alarms or current system conditions will be indicated to the operator on the message display or in conjunction with the customer’s distributed control system. This system requires strict code compliance to obtain insurance acceptance. These codes pertain to both the hardware and software of the system and are the latest technology for burner management accepted in the industry to date.

Flame Safeguard Equipment

All flame safeguard control equipment can be supplied as an integral component of our custom burner management control panels or in a stand alone enclosure. We select and engineer these systems specifically for rotary kiln applications where long flame fronts, various flame wavelengths and extreme dusting can occur. Solid state microprocessor based flame amplifiers coupled with self-checking scanners can easily discriminate between the presence of a flame emitting ultraviolet or infrared wavelengths and any background radiation. Controls meet FM, UL and CSA approval.

Fuel Trains

With single or multiple fuel capability, our pre-assembled valve trains arrive on the job site complete with strainers, regulators, manual blocking valves, automatic shut off valves, vent valves, solenoid valves, gauges, high and low pressure switches, temperature switches and fuel flow control valves with I to P converter and two auxiliary position switches. Units are pre-piped, flanged and mounted on a free standing rack. Pre-wired to a junction box, all valve trains are shop tested before leaving the factory and are engineered to meet NFPA approval.

Pump Sets

Our duplex designed pump sets allow system maintenance with continuous operation and no shut-down necessary. Included on these fully assembled units are two pumps (one operating and one stand-by), duplex inlet strainer, regulator, gauges, pressure relief valves and manual blocking valves. Pump sets can be fitted with duplex heaters (either steam or electric) for heavy oil applications. The entire assembly is shop pressure tested and mounted on a base with flanged inlet and outlet connections ready for field installation.

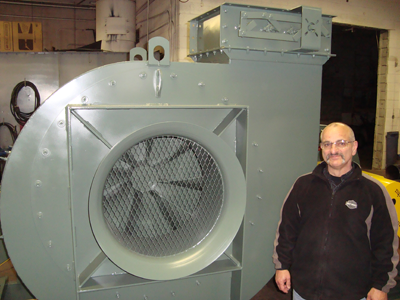

Combustion Air Fans

Primary air requirements for the burner vary depending on the original kiln design parameters. We can engineer and supply a proper combustion air fan ranging from 20 to 100 percent stoichiometric flow.

Burner Support Systems

Our dual rail and trolley overhead burner support carriages allow for projection depth changes and ease of maintenance at annual shutdown time. In addition, the burner can be aimed with simple, easy to perform adjustments with the provided professional quality ratchet wrench. The ability to both shape and locate the flame is critical to achieving the proper heat profile of the kiln. Heavy duty motorized cable winch is also available for ease of retraction and reinsertion.

OEM Parts Support

Precision-made quality components are available for our full line of products. Factory-original parts built to OEM specifications ensure your equipment continues to operate at peak performance and efficiency. Contact the factory today for current pricing and availability.